High purity water is critical to wafer fabrication and semiconductor manufacturing plants (or “fabs”) process and the industry uses a significant amount of water. Ultrapure water is used to rinse and clean silicon wafers as they are manufactured. These plant require Ultrapure Water (UPW), which is thousands of times purer than drinking water. A semiconductor plant can easily use 20 million litres of water per day as part of its manufacturing process.

According to Semiconductor Digest, the power requirements to produce UPW is significant. Semiconductor Digest states “The latest update to S23, SEMI’s guidance for energy use in the fab, assigns a value of 9kWh/m3 to generate cold UPW, and 92kWh/m3 for hot UPW. S23 does not declare a value for wastewater management.

Internally, we have used 4.12kWh/m3 for water and wastewater to and from the abatement system. The energy requirement will be much higher if the water is extensively recycled.”

Source: Semiconductor Digest - www.semiconductor-digest.com/water-supply-challenges-for-the-semiconductor-industry

Nero is willing enter into a consortium with interested parties and provide the water solution to key industries such as electronics.

It make sense for India to implement desalination infrastructure to support both its farming sector and its ambition of trying to create a semiconductor industry. Both industries would use a common infrastructure to support both their water and power requirements.

Nero will enter into a consortium with interested parties and provide the water solution to key industries.

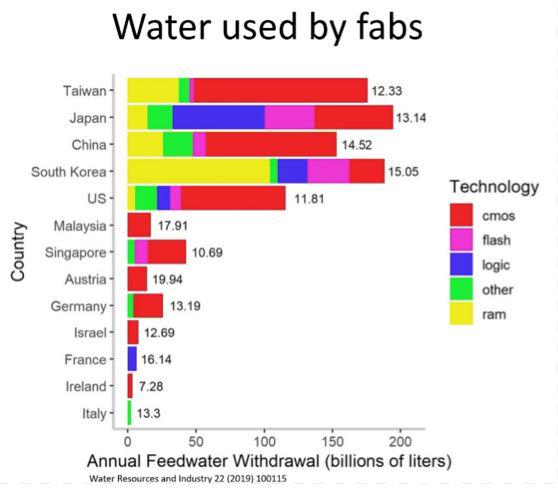

Nero Agro is a reliable provider of water treatment for electronics. Companies in the electronics industry use a moderately high amount of water and energy to power their operations. Facilities draw feedwater for things like cooling equipment and HVAC systems, as well as for other general purposes like maintenance and landscaping. Semiconductor fabrication plants—or "fabs" as they're commonly known— are particularly resource-intensive, as they tend to require lots of energy and water.

This is because they use a polishing process during manufacturing which results in the deposition of a residue on semiconductor chips. To ensure that the chips function as intended, this residue must be removed, and this is accomplished by rinsing the chips with ultra pure water.

Fabs must use significant amounts of water and energy to produce ultra pure water, using water treatment processes like filtration, activated carbon, reverse osmosis, d gasification and electro demonization to remove contaminants and achieve a very high level of purity.

Why Water Treatment is Necessary in the Pharmaceutical Industry?

Due mainly to an increasing emphasis on environmental concerns, and interest in controlling costs associated with sourcing water and disposing of wastewater and brine streams, chip fabs are increasingly adopting water recycling programs to reduce overall water use. In fact, in July 2022, major semiconductor producer Intel announced it achieved net positive water use in the US, Costa Rica, and India, and it has plans to expand the initiative in other countries where it operates.

To achieve these kinds of ambitious goals, those in the electronics industry are increasingly employing water recycling and reclamation initiatives. These types of strategies entail capturing wastewater streams for reuse within the facility. Depending upon the nature of the wastewater, and the target reuse application, treatment needs may range from minimal to moderately involved.

Facilities have flexibility in how they choose to implement reuse strategies, such as by combining multiple wastewater streams for treatment and reuse, or by opting to reclaim only the "cleanest" or most suitable streams, such as by reclaiming used rinse water for cooling.

We at Nero Agro offer water treatment to different sectors at affordable prices. Therefore choose us and get our water treatment system for the electronic industry today.